GD Integra® Rotary Screw Air Compressors The GD Integra Series of air compressors features the latest in technology, innovation and engineering at an economical price. Low dBA level, small footprint, high efficiency and easy serviceability are standard benefits with the GD Integra Series. Integrated Compressor Airend • tate-of-the art, Integrated design S with 25% fewer parts and connection points than conventional designs delivers maximum reliability. • odular airend design offers M a readily accessible bolt-on configuration unlike encapsulated designs that require total replacement. • nternal 3-way thermal mixing valve I minimizes leak points. • hree-stage air/oil separation T involving mechanical redirection, cyclone centrifugal type air flow and a pleated filter with inside out final separation to offer less than 2 ppm carryover before the aftercooler. Flexible, Quality Package Design Acoustic Enclosure • on-corrosive control line tubing N maximizes reliability— minimizes downtime. • tandard enclosure offers low 75 S dBA noise level to ensure quiet operation at any facility. • actfully located controller on T the end of each machine for easy multiple unit installation and sequencing. • asy lift-off panels offer fast and E convenient access to airend and motor. Minimum Energy Use Rotor Design • anufactured in one of the most M automated, capital intensive rotor cutting plants worldwide. Several thousands of these proven airends are in operation worldwide. • otor profile with a short seal line R saves you money in electrical costs by offering high efficiency through reduced opportunities for air leaks. • recise bearing size that prohibits P misalignment. This handles up to 3 times more load capacity than conventional designs to offer you a savings in service costs and extends operation life. Complete Aftermarket Support • omplete line of Gardner Denver C consumables available to ensure the long life of each compressor!

- Standard Equipment. ntegrated, Single-Stage Rotary Screw Air Compressor with I Load/No Load Control. Phase, 60 Hertz, 1.15 Service Factor, EISA Energy Efficient, 3 Open Drip Proof Drive Motor includes 5 year warrantystandard. mall, Compact Footprint S. tandard 75 dBA Quiet Sound Enclosure S. djustable Motor Base A. ackage Mounted Moisture Separator/Trap P. adiator-Type Oil.

- The extensive Gardner Denver distribution network provides superior technical service and support at a local level to keep your equipment operational and in warranty. Don’t take the risk – always use original equipment manufacturer parts and have your equipment serviced by Gardner Denver.

Gardner Denver rotary screw air compressors are well known for their durability and efficient performance across a wide range of customer applications. With so many models to choose from and almost endless customizations, Gardner Denver has the compressor to fit your requirements. Through our global network of authorised distributors, Gardner Denver provides world class maintenance and service support with a team of highly trained and skilled compressor service technicians. From emergency call outs to scheduled preventative maintenance and remote monitoring of compressed air operating parameters.

Open the catalog to page 1GD Integra® Rotary Screw Air Compressors The GD Integra Series of air compressors features the latest in technology, innovation and engineering at an economical price. Low dBA level, small footprint, high efficiency and easy serviceability are standard benefits with the GD Integra Series. Integrated Compressor Airend • tate-of-the art, Integrated design S with 25% fewer parts and connection points than conventional designs delivers maximum reliability. • odular airend design offers M a readily accessible bolt-on configuration unlike encapsulated designs that require total replacement. • nternal 3-way thermal mixing valve I minimizes leak points. • hree-stage air/oil separation T involving mechanical redirection, cyclone centrifugal type air flow and a pleated filter with inside out final separation to offer less than 2 ppm carryover before the aftercooler. Flexible, Quality Package Design Acoustic Enclosure • on-corrosive control line tubing N maximizes reliability— minimizes downtime. • tandard enclosure offers low 75 S dBA noise level to ensure quiet operation at any facility. • actfully located controller on T the end of each machine for easy multiple unit installation and sequencing. • asy lift-off panels offer fast and E convenient access to airend and motor. Minimum Energy Use Rotor Design • anufactured in one of the most M automated, capital intensive rotor cutting plants worldwide. Several thousands of these proven airends are in operation worldwide. • otor profile with a short seal line R saves you money in electrical costs by offering high efficiency through reduced opportunities for air leaks. • recise bearing size that prohibits P misalignment. This handles up to 3 times more load capacity than conventional designs to offer you a savings in service costs and extends operation life. Complete Aftermarket Support • omplete line of Gardner Denver C consumables available to ensure the long life of each compressor!

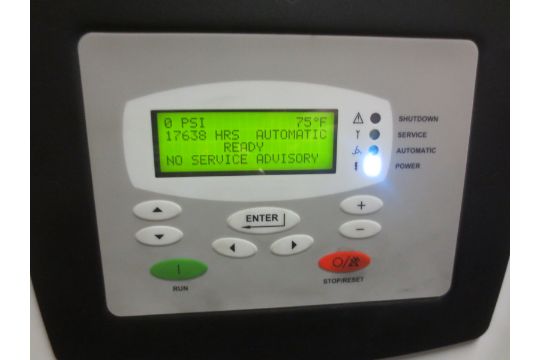

Gardner Denver Integra Air Compressor Service Manuals